Cyclone dedusting equipment

Alias: Cyclone / streamline precipitator

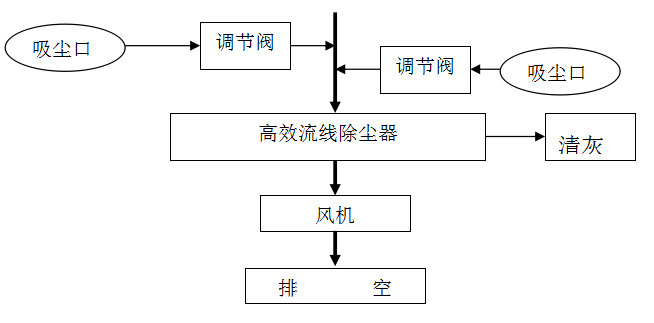

Under the action of the fan, the dust containing gas enters the high-efficiency cyclone dedusting equipment through the pipeline. Through the high-efficiency streamline separation of the high-efficiency cyclone dedusting equipment, the dust is separated into the lower ash hopper, and the purified air enters the clean gas pipeline through the fan and is discharged into the atmosphere.

The dust in the ash hopper and the filter screen in front of the fan shall be regularly and timely removed and cleaned.

Explain:

1 above is the dust system process diagram;

2 the main equipment is in the box;

3. The foundation shall be provided by the owner.

Enterprise service commitment

● the warranty period of equipment and pipeline is one year, during which free maintenance and replacement are required. Upon expiration of the warranty period, the service will be provided at a cost.

● in case of failure or other problems, we will give a response by phone immediately after we get formal notice, and give a response within one hour for general problems. Arrive at the site within 24 hours and solve the problem.

● after the completion of the project, keep in touch with the operation and management personnel of the owner at any time, and send technical personnel to make return visit to the project from time to time. In case of technical problems in operation, we will provide technical consultation free of charge.

1. System startup

1.1 preparation for system startup

Before starting the system, check whether the following items are met:

1) The distribution cabinet has been energized and the voltage meets the requirements;

2) Check the power supply, which should be three four wire wiring;

3) The damper at the air inlet of the suction hood has been adjusted and fixed, and at least one of the air inlets is open;

4) The dust in the ash hopper has been cleaned;

5) The ash discharge valve under the ash hopper has been closed;

6) The dust at the air inlet has been cleaned;

1.2 system startup steps

1) Start the fan and observe the fan to normal operation;

2) Adjust the pipe air regulating valve to the air inlet to absorb dust normally;

2. System shutdown

1) Shut down the fan;

2) Clean up the residual dust at the air intake;

3) Open the dust discharge valve to clean the dust.

3. Precautions

1) During the operation of the system, it is necessary to regularly check whether there is any residual ash at the air intake and clean it in time;

2) Do not bring open fire or Mars into the pipeline to avoid fire;

3) Always check and ensure that the dust discharge pipeline of the dust remover is well sealed.

4) Check the whole system regularly during long-term operation.

5) The impeller is easy to dust or foreign matters must be cleaned at least once every two weeks.

6) The fan bearing and other operation links must be oiled regularly, and it is strictly prohibited to run without oil.

7) Clean the dust and other sundries in the pipeline regularly.

8) Please refer to the operation manual for the precautions of fans and other equipment.

9) The steel wire rope, rotating mechanism and other links must be inspected every month and repaired in time to avoid accidents.

Welcome to ningbo evergreen environmental technology co., LTD.

Welcome to ningbo evergreen environmental technology co., LTD. Welcome to ningbo evergreen environmental technology co., LTD.

Welcome to ningbo evergreen environmental technology co., LTD.