Welcome to ningbo evergreen environmental technology co., LTD.

Welcome to ningbo evergreen environmental technology co., LTD. Welcome to ningbo evergreen environmental technology co., LTD.

Welcome to ningbo evergreen environmental technology co., LTD.

Office Address: 703, Building 1, Miao Huan Power Town, Qingfeng Road, Jiangbei High-tech Zone, Ningbo City, Zhejiang Province

Production Address: No. 3 Zhuhai Road, Chengdong Industrial Park, Xiangshan County, Ningbo City, Zhejiang Province

Sales Department:+86-574-87792453

+86 13081928795

+86 18257419819

Purchasing Department:+86-574-87210884

Administration Department:+86-574-87211844

Fax:0574-87211844

E-mail:nbxyhb@sina.com

QQ:1565081426

Catalytic combustion Activated carbon concentration and desorption Catalytic Combustion (RCO)

Release time:2026-01-07 Click:21A new type of activated carbon (mostly honeycomb carbon or fiber carbon) is applied to adsorb concentrated low concentration of organic waste gas, and hot air is introduced to heat the activated carbon after adsorption is close to saturation, so that the organic waste gas is desorbed into the catalytic combustion bed for flameless combustion purification treatment, and the hot gas is recycled in the system or a secondary heat exchanger is added for heat recovery. In this method, the low concentration of organic waste gas is concentrated into high concentration organic waste gas by activated carbon and then completely purified by catalytic combustion. This method absorbs the advantages of adsorption method and catalytic combustion method, overcomes the disadvantages of separate use, and is a mature and practical method for the treatment of organic waste gas in China.

The main technical principles are explained

(1) Working principle of activated carbon:

The waste gas containing organic matter is absorbed into the activated carbon micropores by the action of the fan and the activated carbon adsorption layer, and the clean gas is discharged by the strong adsorption capacity of activated carbon with large specific surface area. After a period of time, when the activated carbon reaches the saturated state, the adsorption is stopped, and the organic matter has been concentrated in the activated carbon. Catalytic combustion was used to desorption and regenerate saturated activated carbon and put it back into use.

The organic mixed waste gas to be treated is processed by the induced draft fan, and the dust and impurities in the waste gas are removed by the pre-treatment filter device first, otherwise the direct adsorption will block the micro-hole of the activated carbon, thus affecting the adsorption effect or even failure. After the preliminary filtration, the "relatively pure organic waste gas" enters the adsorption device for adsorption purification treatment. The organic matter is trapped inside the activated carbon by the unique force, and the clean gas is discharged into the atmosphere through the chimney. After a period of adsorption, the activated carbon reaches the saturated state. According to the PLC automatic control program, the saturated activated carbon bed and the activated carbon bed are switched alternately. The hot air is sent into the activated carbon bed by the fan to heat up the carbon layer and "steam" the organic matter from the activated carbon. The desorbed exhaust gas belongs to the organic waste gas with high concentration, small air volume and high temperature.

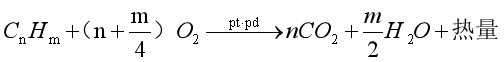

(2) electrocatalytic oxidation ECOCTO working principle: VOC-COCTO type organic gas catalytic purification device, is the use of catalysts to make the combustible components in the harmful gas oxidation decomposition at a lower temperature purification method. For CnHm and organic dissolved steam oxidation decomposition to COCTO₂ and H₂O and release a lot of heat. The reaction equation is:

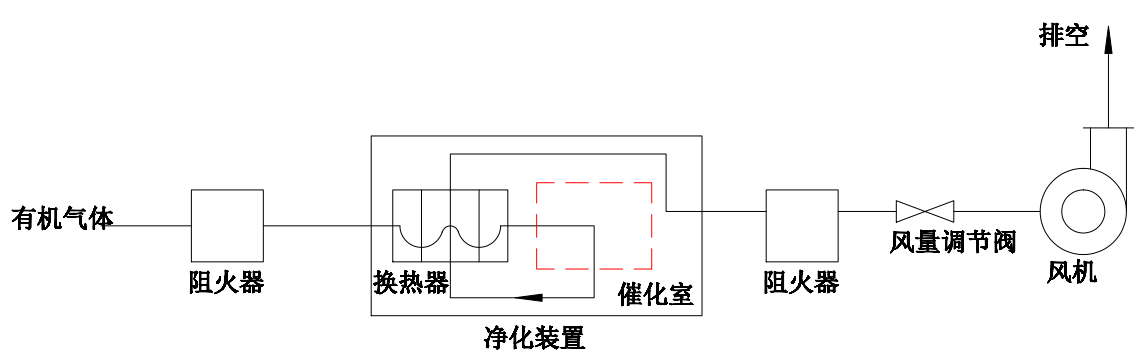

The main structure of the device is composed of three parts: the main engine of the purification device, the induced draft fan and the control system. The purification device includes: fire resistance dust collector, heat exchanger, preheater, catalytic combustion chamber.

FIG. 1 Schematic diagram of VOC-COCTO

After the high concentration, small air volume and high temperature organic waste gas desorbed by activated carbon is filtered by fire retardant dust collector, it enters a special plate heat exchanger and exchanges energy indirectly with the high temperature gas after catalytic reaction. At this time, the temperature of the waste gas source is increased for the first time. The gas with a certain temperature enters the preheater for a second temperature increase; After entering the first stage of catalytic reaction, the organic waste gas is decomposed in the lower part of the low temperature, and the energy is released, and the exhaust gas source is directly heated, and the gas temperature is raised to the optimal temperature of the catalytic reaction. After the temperature detection system detection, the temperature meets the temperature requirements of catalytic reaction, enter the catalytic combustion chamber, the organic gas is completely decomposed, while releasing a lot of heat; The purified gas is converted into cold air through the heat exchanger, and the gas is drained by the induced draft fan after cooling.

Organic matter using its own oxidation combustion released heat to maintain spontaneous combustion, if the desorption gas concentration is high enough, COCTO normal use requires little electric power or even no electric power heating, to achieve real energy saving, environmental protection, at the same time, the whole device is safe, reliable, without any secondary pollution.

703, Building 1, Miao Huan Power Town, Qingfeng Road, Jiangbei High-tech Zone, Ningbo City, Zhejiang Province

Production Address: No. 3 Zhuhai Road, Chengdong Industrial Park, Xiangshan County, Ningbo City, Zhejiang Province

Sales Department:+86-574-87792453

+86 13081928795

+86 18257419819

Purchasing department: +86-574-87210884

Administration department:

+86-574-872118444

Fax: 0574-87211844

E-mail:nbxyhb@sina.com

Complaints and suggestions:

+86-18057401903